When researching construction, you invariably discover that any new or innovative idea has actually been tried over and over again, often stretching back decades. One of these new-but-actually-old ideas is the idea of a mechanical bricklayer, a machine to automate the construction of masonry walls.

It’s easy to see the appeal of this idea—masonry construction seems almost perfectly suited for mechanization [0]. It’s extremely repetitive—constructing a masonry building requires setting tens or hundreds of thousands of bricks or blocks, each one (nearly) identical, each one set in the same way. It doesn’t seem like it would require physically complex movements—each brick gets a layer of mortar applied, and is simply laid in place next to the previous one. And because each brick and mortar joint is the same size, placement is almost deterministic—each brick is the same fixed distance from the previous one.

On top of this, masonry, especially block masonry, is one of the most physically punishing construction tasks, since it requires hours and hours of repetitively moving extremely heavy objects. All together masonry seems like the perfect candidate for a task to hand over to a machine, and it’s something people have been attempting for over 100 years.

Early Attempts

John Thompson’s 1904 bricklaying machine

The first attempts at machine-laid masonry date back to the turn of the century—we can find patents issued for mechanical bricklayers in 1899, 1904, and 1924, all by different individuals (some of whom worked on their idea for years—John Thompson, who was was awarded the 1904 patent, had additional patents in 1918 and 1926). These machines would (theoretically) run along the top of a wall, set down a layer of mortar, and place bricks one at a time. These machines couldn’t sense anything about their environment, or measure where a brick needed to go—they simply extruded a layer of mortar and mechanically placed a brick at regular intervals. It’s unclear how many of these machines ever made it beyond the drawing board, but at least one of these (John Knight’s) was used to build a brick wall that allegedly still stands today.

This same concept would reappear several times over the next few decades—patents can be found for similar machines issued in the 60s and 70s. This video from 1967 of the “Motor Mason ″ shows one in action—it’s not all that different from the early 1900s efforts:

These attempts at mechanical bricklayers never made it far beyond the demonstration stage, and never found any sort of commercial success.

The 1980s: Bricklaying Robots

Beginning in the late 1980s and early 90s, we start to see attempts at mechanizing masonry based around robotic arms. Unlike the previous machines, which were purely mechanical, these machines had an information processing component. Instead of mindlessly repeating the same motions, these arms would combine a high degree-of freedom robotic arm with sensors and control systems to “see” the brick, see where it needed to go, and deliberately grab it and place it there.

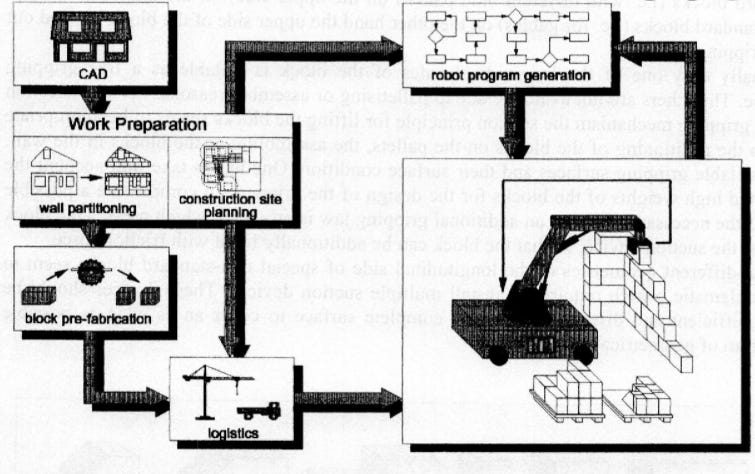

Schematic of the ROCCO system, via IAARC

For a while this was an entire sub-field of academic research—we can find examples in Slocum 1988, Lehiten 1989, Rihani 1996, Altobelli 1993, Pritschow 1996, the SMAS in Japan, and the ROCCO system. But despite all the effort expended, these attempts saw about the same level of success as the previous, purely mechanical masonry machines. Most didn’t get past the level of technical descriptions (“here’s how you COULD build a masonry robot”), a few reached the level of prototypes, but essentially no progress was made beyond that. At least one researcher gave up, declaring that general purpose construction robots would be infeasible for the foreseeable future. The single example I can find of a system that might have been used in production is Multistone 8000, a German system that could, with human assistance, automatically assemble masonry wall panels in a factory-like environment.

Current Attempts

Over the years, masonry has declined in importance as a construction technology in the developed world, and with it the interest in automating it. Unlike with concrete 3D printing, where there are dozens of attempts to develop the technology, I can only find a handful of current efforts to automate masonry.

Hadrian X, via FBR

The most advanced of these seems to be the Hadrian system by Fastbrick Robotics. Hadrian uses a hollow boom mounted to a truck, through which masonry blocks are transported (sort of like a concrete pump truck). When the block reaches the end of the boom, it’s sprayed with an industrial adhesive (instead of conventional mortar) and grabbed by a robot arm, which places it into the correct position.

The reach of this boom, combined with it’s vehicle mounting, means that Hadrian has a lot fewer restrictions as to where it can place blocks than other mechanized masonry systems. It’s capable of placing blocks in tight hallways or complex corners, and Hadrian can construct all the walls of a small building with just a few moves of the vehicle. Hadrian can currently set around 200 blocks an hour, but they’re aiming to be able to do 1000 blocks an hour or more (the blocks it sets are different from the block masonry used in the US, but in US masons can set somewhere in the neighborhood of 400 blocks a day).

Hadrian has been in development since 2006, and has only recently started to be used on commercial jobsites—they’ve built the block walls for 3 or 4 buildings in Australia so far. It seems like they’ve had some struggles as a company (not surprising for a hardware system that’s been in development for over 15 years), and they had what appears to be a fairly serious round of layoffs in 2020. But over the last few months there’s been a slow trickle of projects built using the system.

But the most commercially successful mechanized masonry system I’m aware of is the SAM, semi autonomous mason. SAM is a masonry robot built by Construction Robotics, and has been in use on commercial projects since 2015. Unlike Hadrian, which lays block, SAM lays normal clay bricks—it consists of a robot arm, mortar dispenser and conveyor belt, mounted to a wheeled chassis. The robot arm grabs a brick, applies a layer of mortar to it, and places it into position on the wall, based on an internal “brick map” indicating the location of every brick to be set. Once the brick is in place, it repeats the process, traversing back and forth as it builds up the wall (human masons are required to set bricks at the ends of the wall). SAM has a series of sensors to compensate for the movement of the platform and ensure it’s placing bricks level, and can work with bricks of all different sizes (though it won’t build CMU block walls). It gets mounted to a movable scaffolding that’s raised gradually as the wall is completed.

SAM, via Youtube

Like Hadrian, it also seems like SAM has had some struggles. It can perform well on very long stretches of wall, but on short walls it has trouble outperforming human masons. It can’t turn corners, and it can’t finish the masonry joints. At its best it seems to lay brick around 5 times faster than a human can, but it requires masons to follow behind it to clean the joints and occasionally level the bricks, and an on-site technician to handle technical issues. The book written about the development of SAM documents one challenge after another, and ends with them struggling to find buyers for it. The promotional material on Construction Robotics’ website suggests that it’s no longer their main focus—more emphasis is given to their other product, MULE.

Other than SAM and Hadrian, there are a few other mechanical bricklayers in various stages of development. Craftsmac, a company out of India, just recently announced a robotic mason used for building CMU walls—it appears somewhat similar to SAM, a wheeled chassis with a robot arm, conveyor, and mortar mixer mounted to it. This UK system for robotically laying bricks uses a track mounted system gantry system, which both lets it turn corners and eliminates the problem of how to move the robot from floor to floor (trading it for the time and expense of having to assemble the system upfront). ROB uses an off-the-shelf robot arm to build highly variable masonry panels (though it doesn’t seem to be able to handle mortar). You also see the occasional academic effort. Overall the list of efforts in this space is pretty short.

One area where we do see some commercial success with mechanical bricklaying is with brick roads—a variety of companies offer machines that can “print” a section of road made of bricks. As we’ve seen previously, road construction is slightly easier to mechanize than building construction.

Roadprinter, via Youtube

Masonry Assistants

A slightly different category of machines aimed at improving masonry productivity is what I’ll call “masonry assistants”. These are machines designed to assist with physically lifting the block (they seem to be more common with block than brick) and taking the strain off the mason, while still allowing the mason to manipulate it into position

Masonry assistants date from at least 1994, when the military experimented with MAMA, the Mechatronically Assisted Mason’s Aid. It consisted of a gripper attached to a track mounted boom arm. The mason could use the gripper to move the block into place without having to physically lift it. Since then several companies have developed variations of the boom mounted gripper idea—the Layher Balance, Rimatem, and Assistance System Steinherr were a few I can find records of. The only system like this I’m aware of currently for sale is the MULE, sold by Construction Robotics (they seem to have had much more success with it than with SAM).

The Layher Balancer, via Bock 2015

But the most interesting of these masonry assistant systems might be the exoskeleton in development by FRACO, just released last year. It was adapted from a model developed for the military, and has various passive and active lifting mechanisms designed to reduce the strain on the mason’s muscles when manipulating blocks.

FRACO exoskeleton, via Masonry Magazine

Of course, a machine to aid the moving of heavy objects isn’t exactly revolutionary—a commenter on the agricultural productivity article pointed out that one of the most important advancements in masonry productivity was the telescopic handler, which eliminated having to manually move pallets of block into place on the jobsite.

Why aren’t mechanical masons already here?

Masonry seemed like the perfect candidate for mechanization, but a hundred years of limited success suggests there’s some aspect to it that prevents a machine from easily doing it. This makes it an interesting case study, as it helps define exactly where mechanization becomes difficult—what makes laying a brick so different than, say, hammering a nail, such that the latter is almost completely mechanized and the former is almost completely manual?

There seems to be a few factors at work. One is the fact that a brick or block isn’t simply set down on a solid surface, but is set on top of a thin layer of mortar, which is a mixture of water, sand, and cementitious material. Mortar has sort of complex physical properties—it’s a non-newtonian fluid, and it’s viscosity increases when it’s moved or shaken. This makes it difficult to apply in a purely mechanical, deterministic way (and also probably makes it difficult for masons to explain what they’re doing—watching them place it you can see lots of complex little motions, and the mortar behaving in sort of strange not-quite-liquid but not-quite-solid ways). And since mortar is a jobsite-mixed material, there will be variation in it’s properties from batch to batch.

Masonry machines have constantly struggled with the mortar aspect of masonry; many of them simply ignored the aspect of the problem. The academic studies of the late 80s and early 90s were often based on using mortarless walls, wall systems that don’t require mortar joints (such as surface bonded masonry), or mortar alternatives that behaved a little more predictably (which is what Hadrian ended up using). In his 1996 paper, Pritschow comes right out and says that trying to solve the problem of handling mortar is too difficult. The folks that have figured out how to reliably apply mortar still can’t quite manage to produce a clean mortar joint—they simply slather the mortar on there, requiring workers to follow behind and clean it up. In some ways efforts like SAM don’t look all that different from the 50-year-old Motor Mason in this regard.

Mortar joints make setting blocks more complicated. Whereas a nailgun can apply force to a nail and get a fairly uniform result every time (and if it can’t, it’s not critical—a nail will still function if its driven slightly askew), setting a block on a layer of field-mixed non-newtonian fluid isn’t so forgiving. Without some feedback from the environment (measuring the levelness of the block that’s been set), it’s hard to be sure that the wall is being built level. Human masons are constantly checking the levelness of their blocks with strings or field levels to ensure the wall remains true as it gets built, and making slight adjustments as needed; a mechanical mason needs some way to do the same. SAM seems to have MOSTLY solved this problem, but every so often still needs the workers following behind to tap the blocks level.

This is one of the main things that separates driving a nail from setting a block—the necessity of making adjustments based on feedback from the environment. Things like nailguns, circular saws, and other power tools are in some sense more like the masonry assistants—they perform some purely physical task, while leaving all the information processing and precise placement work in the hands of humans. A nailgun isn’t responsible for figuring out where a nail needs to go, and moving itself into position—it simply does the physical task of striking the nail.

The history of routers and milling machines offers an instructive parallel. The first ones were developed in the late 1800s/early 1900s, and the capability for programmatically controlling them was developed in the late 40s/early 50s. But it’s only recently where we’ve had the capability of incorporating real-time feedback, enabling products like the Shaper Origin (a handheld router that autocorrects human movements ). Robustly getting a machine to react based on its surrounding environment remains a complex problem, even if the machine is physically capable of doing it.

Shaper Origin, via ShaperTools

There’s also a few other ancillary problems making masonry machines tricky:

Bricks and blocks are large and heavy, which means larger, more expensive machinery is needed to manipulate them (especially if you want to manipulate them quickly, as force scales with acceleration).

In the US, masonry walls are constructed with a large amount of reinforcement, which would be difficult to handle for a simple block-based machine (on Hadrian’s projects, the reinforcement was installed manually)

For risk-aversion reasons, it’s hard to get contractors on board with your technology [1]. A surprisingly candid video from Construction Robotics goes into detail about how difficult it was to convince a particular client to use their system, and the book about the company details many more difficult sells.

Should we expect to see mechanized masonry get more popular?

This is a tough question to answer. Fundamentally, it seems like it depends on what progress in robotics, software, computer vision, and other technologies (which I’ll lump together as “automation”) looks like.

For all it’s difficulties, masonry has been more successfully automated than other building systems—it’s one of the few systems where commercial robots for building it are actually on the market for general use. So progress in automation technology might plausibly benefit masonry construction most of all, as it’s arguably the farthest along. If automated masonry systems got smaller, faster, could more easily handle corners and finish joints, it might start to look like a very attractive system.

However, it could just as easily be a rising tide lifts all boats scenario—advancing automation technology could easily be applied to other building systems (wood, steel, etc.) as well. It becomes a question of a question of what the relative improvement curves look like—what gets better the fastest, how long does that stay true?

Blocks are quite heavy, which means the machines to manipulate them will likely always be more expensive than the machines for manipulating a lighter building system. And even large blocks individually make up a small fraction of the overall building. So automated masonry systems might end up being more expensive and have lower production rates than other building types. We could see a situation where there’s a small window of time where automated masonry becomes extremely popular/competitive, but then is quickly overshadowed as the technology gets adapted for other building systems.

[0] - There are, roughly, two different kinds of masonry. Brick masonry, which is made from clay bricks, and concrete masonry (CMU, or concrete masonry units), which is made from hollow concrete blocks. To a first approximation, in the US brick masonry is purely decorative and doesn’t support the weight of the building. Block masonry is used as the load bearing structure.

[1] - The SAM book details quite a few instances of cascading failures caused by process changes. On one job, SAM is unable to set bricks because the wall is unbraced, and the bricklaying platform is much heavier than the ones the firm was used to using, and the wall has insufficient bracing force. The entire project is slowed down. On another project, SAM is slowed down by the masons unexpectedly changing the size of the bricks, which forces them to recreate the brick-map used to program the machine.

I’ve followed your work on Construction Physics, Brian, and I’ve enjoyed it immensely and learned a ton!

Some thoughts:

One of the recurring points you bring up is that construction is limited in cost savings due to the transportation costs—building materials are generally heavy and have low value-to-weight ratios, so centralized manufacturing doesn’t help nearly as much as it does in other industries. That being said, do you see a solution space where the brick-making machine (including kiln if necessary) can itself be brought to the jobsite, with the material being sourced from super-local dirt/clay? I’m picturing almost a portable manufacturing pipeline, where a digging machine feeds dirt into a mixer, which deposits material into a brick mold which is then fired. The resulting bricks are assembled via robots.

Do you think an alternative to mortar could be found? Perhaps a solid resin of some sort that is laid between bricks during placement, and then heated into a liquid and cooled back solid to bond with the bricks?

Do you think the market for automated bricklaying is going to disappear as 3D printing buildings becomes more common/economical?

Looking forward to your continued work!

Thanks!

Re: portable brick machine, I think automation would have to advance a lot before something like this ended up being cost effective (and the resulting automation could probably do a lot of other, more interesting things than just “assemble bricks”)

Re: mortar, folks are already doing this (this is what fastbrick robotics uses, basically)

Re: 3D printing, I don’t think this is especially likely, mostly because people want brick specifically because of how it looks—it’s already a sort of cost-inefficient system that people choose for the aesthetics. Adding another system to the mix doesn’t seem like it would change this calculus, even in the event it becomes super efficient (which seems unlikely to me).